Products

|

Product Name:

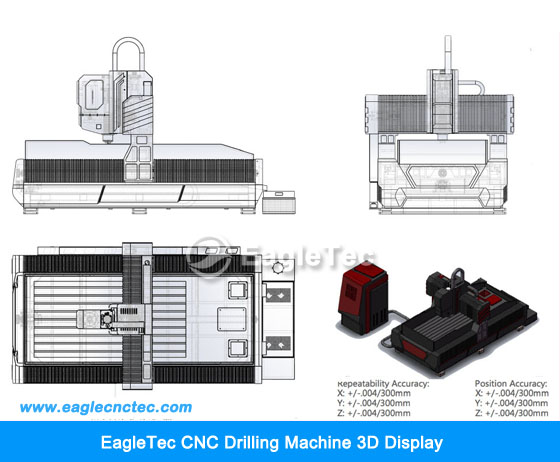

CNC Drilling Machine for Plate & Rectangular Tube Metal Steel Iron Tapping & Drilling 1000x2000mm

No. :

ET Drill – 1000x2000mm

|

EagleTec CNC Drilling Machine Precision

The actual accuracy of EagleTec drilling machine is ±0.04/300mm, both the positioning accuracy and the repeated positioning accuracy.

After each machine is assembled, we use dialgage and marble square ruler to test the accuracy of the machine to ensure that the machine is up to the precision standard (±0.04/300mm) before it delivery.

To prove this, please watch the video of actual test below:

Application

EagleTec CNC drill is applied to processing industries like metal plate, steel rectangular tube, flange, square linear guides and tec. Can do drilling, tapping, counterbore, chamfering, and light milling jobs.

EagleTec CNC Plate Drilling Machine Description

The bed, column, worktable and gantry are HT250 castable parts. They are annealed at high temperature before processing, then annealed twice after semi-finishing, then finished, to ensure that the lathe machine has enough rigidity and stability for metal material machining.

The working platform is cast as a whole, then the T-slot is finely milled out by the CNC machining center and the table surface is refined to ensure the accuracy of the work table.

The drill machine is mainly composed of frame, working table, gantry, power head, numerical control system, cooling system and so on.

The gantry cnc drill machine adopts gantry-moving construction.

The EagleTec cnc drilling machine has three motion axes. The gantry beam is equipped with 45mm Hiwin square linear guide, the slide plate can be moved right-and-left along the guide rail (X axis); the machine body is equipped with a 45mm linear guide rail, the gantry can make fore-and-aft motion along the guide rail (Y axis); and the linear bearing is installed on the slide plate. The power head is equipped with guide rail, the power head can make vertical motion on the slide board (Z axis).

All X/Y/Z axes are driven by CNC closed loop servo motor with high precision rolling ball screw transmission.

The spindle of the power head adopts precise mechanical spindle, driven by servo spindle motor, speed can be stepless adjusted according to the machining requirement. Spindle can be mounted with drilling bit, tap or milling cutter via BT40 spindle taper, equipped with pneumatic cutter cylinder, to achieve a key tool change and higher accuracy.

The cnc drill press machine adopts water-cooled cooling system, equipped with coolant supply, recovery, circulation system, equipped with automatic oil lubrication system, to ensure the linear guide rail and ball screw smooth and effective work for a long time.

Controller adopts the SIEMENS numerical control system, the driving motor adopts the high precision absolute value series servo motor, with the color display screen with USB interface; equipped with all digital high-speed manual pulse generator (MPG), makes your operation more convenient and faster.

To ensure the reliability of the cnc drilling machine, all the key parts are adopted imported quality products. Please see the import parts list for details.

Technical Parameter

|

Model No. |

EagleTec-1000x2000 |

|

|

Maximum Machining Size |

L x W (mm) |

1000x2000 |

|

Thickness (mm) |

220 |

|

|

Vertical sliding pillow drilling power head |

Quantity |

1 |

|

Spindle Taper |

BT40 |

|

|

Borehole Diameter (mm) |

Ø1 ~ Ø34 |

|

|

Tapping Diameter (mm) |

M3 ~ M16 |

|

|

Spindle Speed Range (rpm) |

30 ~ 3000 |

|

|

Spindle Servo Motor Power (kw) |

5.5 |

|

|

Distance between spindle bottom to the table |

200 ~ 600mm |

|

|

X Axis |

Maximum Stroke (mm) |

1000 |

|

X Axis Speed Range (m/min) |

0~9 |

|

|

X Axis Servo Motor Power (kw) |

2.4x1 |

|

|

Y Axis |

Maximum Stroke (mm) |

2000 |

|

Y Axis Speed Range (m/min) |

0~9 |

|

|

Y Axis Servo Motor Power (kw) |

2.4x1 |

|

|

Z Axis |

Maximum Stroke (mm) |

370 |

|

Y Axis Speed Range (m/min) |

0~8 |

|

|

Y Axis Servo Motor Power (kw) |

2.4x1 |

|

|

Machine Dimension |

L x W x H (mm) |

3500x2100x2200 |

|

Three Axis Positioning Accuracy |

X/Y/Z |

±0.04mm/300mm |

|

Repositioning Accuracy |

X/Y/Z |

±0.04mm/300mm |

|

Gross Weight |

KG |

5000 |

Imported Parts List

|

Item |

Brand |

Origin |

|

Square Linear Guide & Bearing |

HIWIN 45mm |

Taiwan (China) |

|

Rolling Ballscrew |

HIWIN 4010 |

Taiwan (China) |

|

CNC Controller |

SIEMENS |

Germany |

|

Absolute Servo Motor |

SIEMENS |

Germany |

|

Spindle Motor |

SIEMENS |

Germany |

|

Spindle |

BT40 Denamu |

Joint Venture |

|

Pneumatic Cutter Cylinder |

AirTAC |

Taiwan (China) |

|

Electronics |

Schneider |

France |

|

Electronics |

Omron |

Japan |

|

Auto Lubricator |

Hurun |

Taiwan (China) |

For any further information regarding this cnc drilling machine, please inquire now.