How to Connect a New Fuling Inverter VFD To Your CNC Router I CNC Tutorials

EagleTec-CNC is a specialized company for building cnc machines of great quality and providing best afer-sales support to our customers. Because some too many friends have asked us for assistance, we only share knowledge now and do not provide free technical support to friends we don’t know; please understand.

Of course, for our customers, we will always provide the best free technical support to them.

This tutorial applies to DZB200, DZB280 and DZB300 Fuling inverters which includes models below: DZB280B001.5L2DK, DZB280B002.2L2DK, DZB280B003.7L2DK, DZB280B001.5L4DK, DZB280B002.2L4DK, DZB280B003.7L4DK, DZB280B005.5L4DK, DZB280B007.5L4DK, DZB280B011.0L4DK, DZB280B018.5L4DK

DZB300B0015L2, DZB300B0022L2, DZB300B0037L2, DZB300B0037L4, DZB300B0055L4, DZB300B0075L4, DZB300B0110L4, DZB300B0185L4

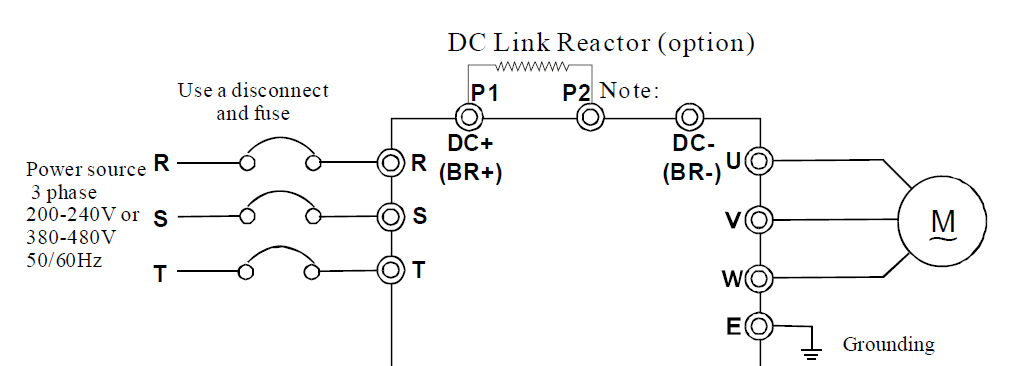

First, let’s look at how the main circuit is wired. See wiring diagram below:

As shown in the circuit diagram above, R、S、T (L、N) are AC power input terminals. U、V、W are for spindle motor connection.

R,S,T – should connect with the main input power wire L1, L2, L3 (3 phase input model)

L,N – should connect with the main input power wire L, N (single phase model)

U,V,W – should connect to the spindle motor terminal

The wiring of the main circuit is easy.

Second, let’s look at how the control circuit is wired. Control loop refers to the wiring between fuling inverter control terminal and numerical control system. This part is a little complicated. The connection is different according to different cnc controllers. Because there are too many different cnc controllers, let's see the wiring of the control loop with two more common systems, RichAuto DSP A11 and Weihong NC studio.

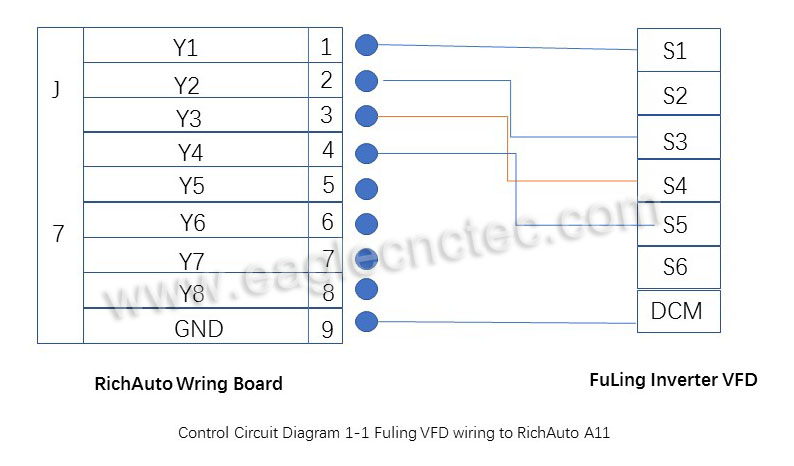

1) RichAuto AutoNow DSP A11 and Fuling Inverter wiring:

From above wring diagram, we can see that, J7 terminal on RichAuto wiring board needs to be connected with the fuling inverter control terminal. Details below:

Y1 on RichAuto board goes to S1 on Fuling VFD

Y2 on RichAuto board goes to S3 on Fuling VFD (S3 is multi-speed phase 1)

Y3 on RichAuto board goes to S4 on Fuling VFD (S4 is multi-speed phase 2)

Y4 on RichAuto board goes to S5 on Fuling VFD (S5 is multi-speed phase 3)

GND on RichAuto board goes to DCM on Fuling VFD (DCM is common port)

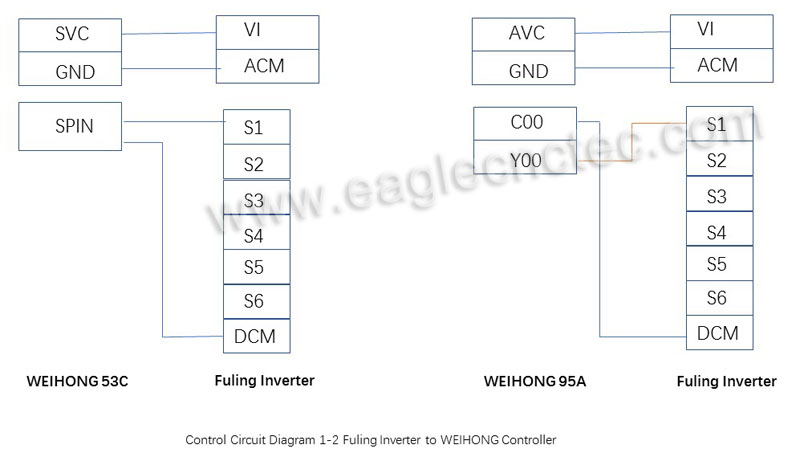

2) WEIHONG NC Studio and Fuling inverter wiring:

One point, different with RichAuto, WEIHONG NC studio uses analog quantity to control the speed of spindle, instead of multi-speed control. Details below:

Old version weihong 53c nc studio

SVC on WEIHONG NC studio board goes to VI on Fuling VFD

GND on WEIHONG NC studio board goes to ACM on Fuling VFD

Two ports of SPIN on WEIHONG NC studio, one goes to S1 on Fuling VFD, the other goes to DCM on Fuling VFD.

Update version weihong 95a nc studio

AVC on WEIHONG NC studio board goes to VI on Fuling VFD

GND on WEIHONG NC studio board goes to ACM on Fuling VFD

C00 on WEIHONG board goes to DCM on Fuling VFD.

Y00 on WEIHONG board goes to S1 on Fuling VFD

Reminder: there is no need to do multi-speed wiring for WEIHONG NC studio, as it is using analog voltage frequency instruction to control the speed of spindle motor.

After wiring finished, next step is set up the parameters for Fuling inverter.

If need any assistance, please feel free to contact us.

Original post from Jinan EagleTec Machinery Co.,Ltd.

Repost please indicate the source.

【 Go Back 】 | 【 Close this window 】