What you need to know: CNC Wood Turning Lathe Job Design Pattern Programming

In the previous article, we mainly talked about the detailed steps and basic principles of CNC wood turning lathe programming. In this post, we are going to talk about several key points you should know in the programming process. You can work out the correct jobs only after you understand what is saying in this post.

Some users may encounter this error when initially using a cnc wood lathe, that is, the circle pattern in the balustrade is not completely machined. The part marked with a yellow circle as shown below:

Why does the wood turning job have this error?

The reason is probably caused by the fact that the operator did not properly set the shallowest cut depth when do programming. Exactly, the shallowest cut depth is the first point we are talking here.

Shallowest cut depth for computer wood lathe

Our blocks are square shape and we want to mill a complete circle in a square. How to do that?

First, we introduce a mathematical concept, which is the inscribed circle of the square. If a circle is exactly tangent to the four sides of the square, the circle is called the inscribed circle of the square, and the circle is just inside the square. The inscribed circle is the largest circle inside the square.

Same way, this inscribed circle is the largest circle we can mill from a square block with a woodworking cnc lathe.

So the question is how much cut depth do we need to set in order to machine this largest circle? We take an example to explain how to calculate this cut depth.

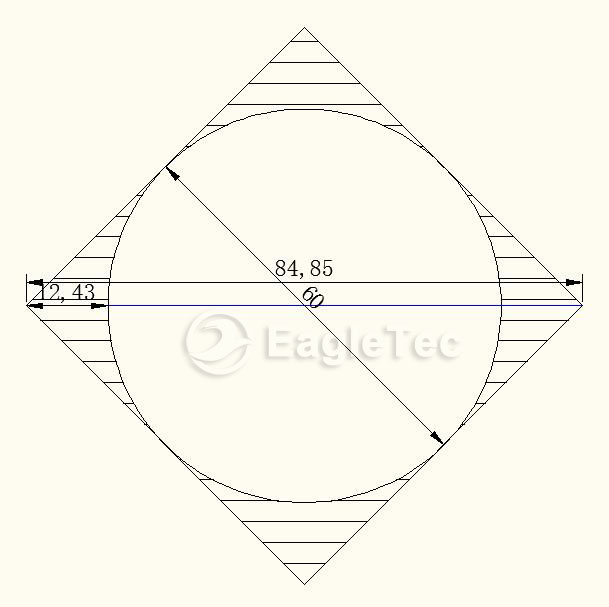

Suppose our block is a wooden square with a side length of 60mm. According to the common sense of mathematics, we can conclude that the inscribed circle diameter of this wooden square is also 60mm, and we can also calculate the diagonal length of the wooden square is 84.84mm. (Note: According to the Pythagorean proposition, diagonal length = side length multiplied by 1.414=60x1.414=84.84). Please refer to the following diagram:

From the figure we can see that in order to get a complete inscribed circle, a reasonable depth of cut should be (84.84-60)/2=12.42mm. This value is also the theoretical shallowest cut depth; In practice, we will set it to be slightly larger than the theoretical value (12.42) by 3 to 5 mm. If the shallowest cutting part does not reach this value when programming, there will be incomplete circumferential machining just like the above image shows.

Offset setup in cnc wood lathe controller

So, except this point, is there any other reason for the above error?

In this case, if the error occurs in the middle of the workpiece and does not appear at both ends, there is no other reason. If the error occurs at the end, we should also consider the offset parameter settings in the cnc wood lathe controller.

The correct offset value should be the exact tool spacing of the two wood lathe carbide tools

Deepest cut depth of programmable wood lath

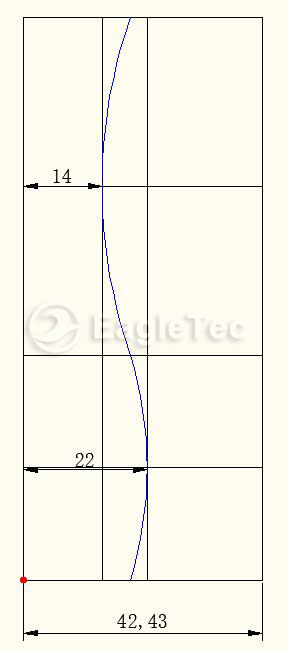

In the drawing process, in addition to the shallowest cut depth, we must also well set the deepest cut depth. A reasonable setting should be less than a half of the diagonal of the square block. If using the above example, the corresponding deepest cut depth should be less than 42.42mm. If the deepest cutting point is equal to or greater than this value, the workpiece will be cut off.

As shown in the picture above (line in blue), a reasonable programming interval should be between the shallowest depth of cut and the deepest depth of cut. (12.42mm<reasonable interval<42.42mm)

If you have different opinions, please feel free to discuss.

Related Tutorials & Course:

How to make a design for broaching

Original post from Jinan EagleTec Machinery Co.,LTD.

Re-post please indicate the source.

【 Go Back 】 | 【 Close this window 】