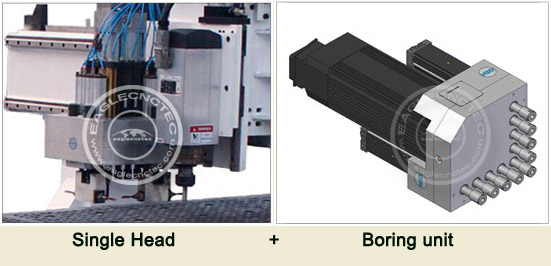

Nesting machine model.EA-1325RD is combined construction of basic type cnc router and Italy boring unit. The boring unit gives this CNC wood cutter big advantage on boring jobs. Boring unit contains 7 vertical drills, which makes the machine bore very fast during machining. In addition, nesting software makes the CNC nesting machine cut very fast. It is a CNC cutter special for office furniture and other panel furniture production.

Suitable Industry

Office furniture, Panel furniture, Wood cabinet and Customized furniture.

Machining Capacity

Engraving, Milling, Boring, Cutting, Trenching

Main Configuration of Nesting Machine

1) China 6.0KW air cooling spindle

2) Taiwan SYNTEC controller

3) Taiwan Delta servo drive and Delta servo motor

4) Origin Italy 7 vertical boring unit

Features of Panel Furniture CNC Cutter

1) Big machining capacity include Engraving, Milling, Boring, Cutting, Trenching

2) Using with nesting software, improves the utilization of material to the max extent.

3) Boring unit improves drilling process during machining largely

4) It is economic version, high-end P.T.P maching center available also.

Technical Parameter

Working Stroke | 1300×2500×200mm

Controller | Taiwan SYNTEC

Motor | Delta Servo

Repositioning | ±0.02mm

Resolution | ±0.0025mm

Spindle | China 6.0KW air cooling, 6000-18,000 rpm

Max. Idling Speed | 60m/min

Max. Cutting Speed | 25m/min

Linear Guide | Taiwan Hiwin

Vacuum Pump | 5.5KW, air ring, 160CBM/h

Body | Heavy duty

Small Electronics | Schneider, Omron, CHINT

Net Weight | 2200KGS

To learn more concerning nesting machine, please inquire now !

【 Go Back 】 | 【 Close this window 】