Digital wood carver is also known as cnc wood router. The model EA-1325CT adopts the built-in electronic cabinet, which is small footprint. Small footprint makes the machine suitable for home shops. This is the greatest feature of this digital wood carver machine. Equipped with water cooling spindle, which is ideal for both carving and cutting works. The unique industrial plug design makes the electrical components of the cnc wood router machine more stable and durable. This machine is the right one for general use and beginners.

Applicable Industries

Digital wood carver is generally used in such industries: Furniture, Cabinetry, 3D Carving, Acrylic Fabrication, Aluminum Fabrication, Architectural Millwork, Exhibits and Fixtures, Sign making, Arts and Crafts, Boat Building, Musical Instruments and more.

Applicable Materials

Materials best for digital wood carver EA-1325CT: Acrylic, MDF, ACM, Melamine, Copper, Phenolic, Brass, Plywood, Aluminum, HDPE, PVC, Solid Surface, Foam, Solid Wood.

White expanded PVC, ACM, PS and more.

Features

1. Adopt build-in electronic cabinet design small footprint.

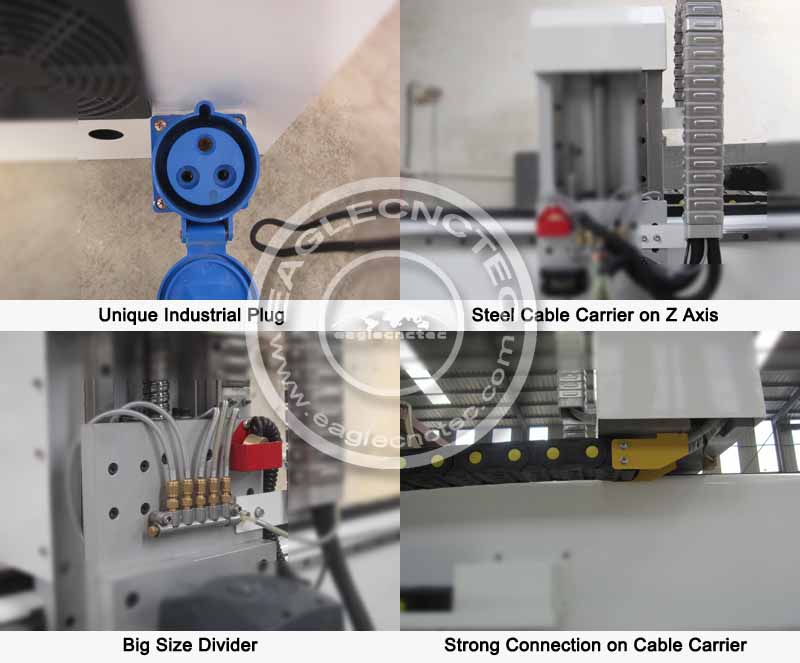

2. The unique industrial plug design makes the electrical components of the digital wood carver machine more stable and durable.

3. Z axis cable is covered by steel cable chain, not easy to damage.

4. The lubrication system is with large diameter divider, which is no blockage.

5. Using automotive paint technology makes cnc wood router machine appearance more beautiful and fashionable.

6. Frame is welded with seamless steel structure; processed by high temperature tempering

treatment and vibrating stress relief (VSR) to reduce residual stress; and it is supported by 6

legs with adjustable leveling feet.

7. Beam is made of steel. A steel beam is superior to a aluminum in its ability to suppress

and absorb the forces created during cutting. It is internally ribbed in order to stiffen the

assembly; this design is minimizing the vibration while increasing accuracy and repeatability.

8. The X and Y axis motion is via a rack and pinion drive, which is hardened for extremly

long life and ground for a very good accuracy; The Z axis is driven by a hardened Germany rolling antibacklash ball screw.

9. Each axis of motion is supported on high precision linear guide ways. Hiwin linear guides allow for higher feed speeds and a better quality of cut.

10. The Y-axis uses a dual drive, one for each side of the gantry.

11. Well compatibility: CAD/CAM designing software e.g. Type 3/Artcam/UcanCAM etc.

12. Has the function of re-carving after break point and power failure.

Main Configuration of CNC Wood Router EA-1325CT

1. Working size 1300x2500x200mm, 8x4 feet

2. 3.0kw water cooled spindle

3. Leadshine DMA860H driver

4. 450B stepping motor

5. Richauto DSP controller A11

6. Container Loading Capacity: 6PCS/20GP, 12PCS/40GP

Optional Configuration of this machine

1. Spindle

Water cooling 4.5kw, 5.5kw

Air cooling 3.5kw, 4.5kw, 6.0kw, 7kw

2. Driver

YAKO 2811MA

3. Controller

Weihong DSP NK105G2

NC studio controller PM53C

Optional Device

Industrial Dust Collector

Technical Parameter of Digital Wood Carver

XY Stroke | 1300x2500mm

Z Feeding Height | 200mm

Z Stroke | 200mm

Spindle | Water cooled, 3.0kw, 24,000RPM

Collet | ER20, router bits shank diameter from 3.175 to 12mm

Driving Motor | Stepper

Max. Idel Motion Speed | 25,000mm/min

Max. Routing Speed | 15,000mm/min

Controller | Richauto DSP A11

Working Table | Aluminum profile

XY Transmission | Helical rack and pinion

Z Transmission | TBI Rolling balls crew

XYZ Linear | PMI rail and bearing, origin from Taiwan

Working Power | AC380V/50-60Hz, 3 Phase 4 Wires

Max. Power Consumption | 7KW (spindle included)

Net Weight | 1100KGS

【 Go Back 】 | 【 Close this window 】