This product is Delta servo drive ASDA-B2 Series model. ASD-B2-0721-B(750W). It drives 750W Delta servo motor. Delta servo driver and Delta servo motor consist one complete set of Delta servo drive system. High-performance, cost-effective Delta servo drive system is always used on cnc router nesting machine and auto tool change cnc router machine. The power rating of the Delta servo drive ASDA-B2 series ranges from 0.1kw to 3kw. The superior features of this series emphasize built-in functions for general-purpose applications and saving the cost of mechatronics integration. Delta servo drive ASDA-B2 makes it convenient to complete the setting of assembly, wiring and operation.

Delta Servo Drive Available Power: 100w, 200w, 400w, 750w, 1.0kw, 1.5kw, 2.0kw, 3.0kw

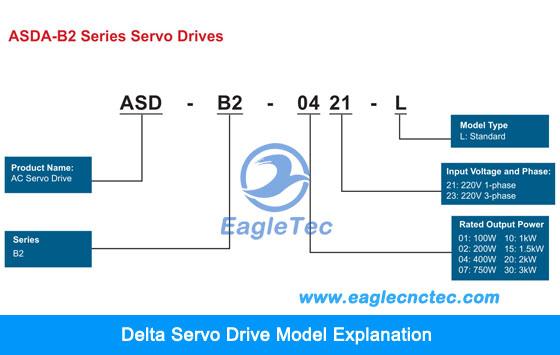

Delta Servo Drive Models (ASDA-B2 series) EagleTec Provides: ASD-B2-0121-B (100W), ASD-B2-0221-B(200W), ASD-B2-0421-B(400W), ASD-B2-0721-B(750W), ASD-B2-1021-B(1.0KW), ASD-B2-1521-B(1.5KW), ASD-B2-2023-B(2KW), ASD-B2-3023-B(3KW)

Delta Servo Drive Optional Accessories:

Power Cables

1) 3m and 5m standard cables are available.

2) Individual power connectors are also provided for different demands.

3) Two types are selectable: with brake and without brake.

CN1 I/O Connectors

1) Used to connect to cnc router controller

2) Delta Part Number: ASDBCNDS0044

Encoder Cables

1) 3m and 5m standard cables are available.

2) Individual encoder connectors are also provided for different demands.

Delta Servo Drive ASDA-B2 Series Features

1. High Performance Precise Positioning Control

1-1. Delta ASDA-B2 series servo drives support 17-bit and 20-bit encoders. It satisfies the demand of high-precision positioning control and stable operation at low speed of cnc router.

1-2. Applying the encoder with a higher resolution can reduce the cogging torque and improve the motor’s precision.

1-3. High speed computing performance: up to 550Hz frequency response and setting time is below 1ms.

1-4. It only takes 10ms to accelerate from -3000r/min to 3000r/min when running without load.

2. Meet diverse command control requirements

2-1. Three command control modes available: Built-in position, Speed, and Torque. (Speed and Torque mode can be controlled by internal parameters or analog voltage).

2-2. High speed differential command (up to 4Mpps) for high precision positioning control.

2-3. Three notch filters are provided to suppress the mechanical resonance efficiently and make the system operate more smoothly.

2-4. Lead friction compensation parameter is specified for the application of circular interpolation, Z-axis motion and ball screw to reduce the loading of the controller.

3. Offers Easy-To-Install Solution For Simple Start-Up

3-1. Delta servo ASDA-B series share the same power cables and encoder cables for easy installation and setup without extra accessories.

3-2. Delta servo motor provides brake, oil seal, and other optional configurations for different applications.

3-3. Separated power supply for main circuit and control circuit is easier to maintain the mechanism.

3-4. 400W or above Delta servo drives have built-in regenerative resistors, which simplify wiring and reduce the installation cost.

3-5. Individual connector (2 sets) for analog signal output, which also simplifies the wiring

Besides Delta servo drive, complete set delta servo drive system (include motor and driver) is also available for you.

To see more detailed photos of this product, please check the video below.

Get all cnc router spare parts by one stop shopping here. Payment can be made by Western Union, Paypal, and Bank Transfer. Please inquire now !

【 Go Back 】 | 【 Close this window 】