This CNC wood router EA-1325VH is adopted heavy duty body construction design. As a heavy duty cnc router, the frame must be welded with thick-wall steel tube; and compared with common frame, it use more steel tubes as well. Both points increase the total weight of machine a lot and achieve better machining stability than common duty machine.

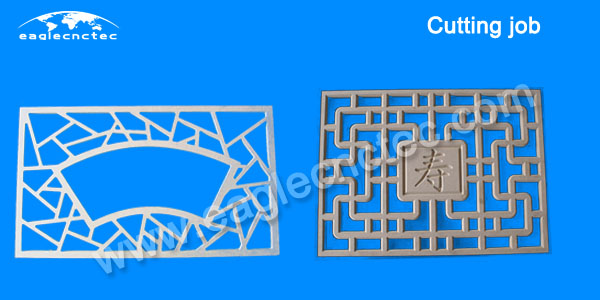

The materials best for heavy duty cnc router is solid wood, MDF, PVC, acrylic, aluminum and brass.

This machine is adopted heavy-duty construction to match the special production need, but the common-duty construction can meet most production request. For common duty type machine, please refer to 4x8 cnc router

Industry

Panel furniture, office furniture, wood door, art wall, slatwall, house decoration, sign cutting and artworks.

Features of EagleTec Heavy CNC router 1325

1) Heavy duty frame design achieve better machining stability; welded with seamless steel and processed by VSR treatment to reduce residual stress.

2) Adjustable leveling feet design can guarantee the working table level very well even the wood router is located on a floor which is not plane.

3) PVC vacuum table with T slot piece embedded, the block can be hold by vacuum sorb as well as by clamp.

4) The X and Y axis motion is via a rack and pinion drive, which is hardened for extremly

long life and ground for a very good accuracy; The Z axis is driven by a hardened rolling antibacklash ball screw.

5) Each axis of motion is supported on high precision linear guide ways that allow for higher feed speeds and a better quality of cut.

6) The Y-axis is adopted dual drive design, one motor for each side of the gantry.

7) Controller is DSP, which has the function of re-carving after break point and power failure.

8) All the linear guides are centrally lubricated from a central lubrication system.

Technical Parameter

XYZ Stroke | 1300×2500×200mm

Construction | basic type cnc with heavy duty frame

Z Feed Height | 200mm

Frame | Heavy duty design with strengthen support plate on two sides

Table | PVC vacuum with T-slot embedded

Leveling Feet | With

Spindle | Air cooled 4.5kw, 0-18,000 RPM

Controller | DSP

Drive Motor | Stepper big power

Driver | YAKO 2811MA

Vacuum Pump | Air-ring, 5.5KW, air flow 160CBM/h

Small Electronic | Schneider, Omron and CHINT

Software | ArtCAM, UcanCAM and Type 3

Command | G code

Max. Idle Run Speed | 35,000mm/min

Max. Cutting Speed | 20,000mm/min

Power Supply | AC380V/50Hz, 3Ph 4 Wires

Max. Power Consumption | 14KW

Net Weight | 1800KGS

Everyone in our team is ready for you, please inquire now !

【 Go Back 】 | 【 Close this window 】