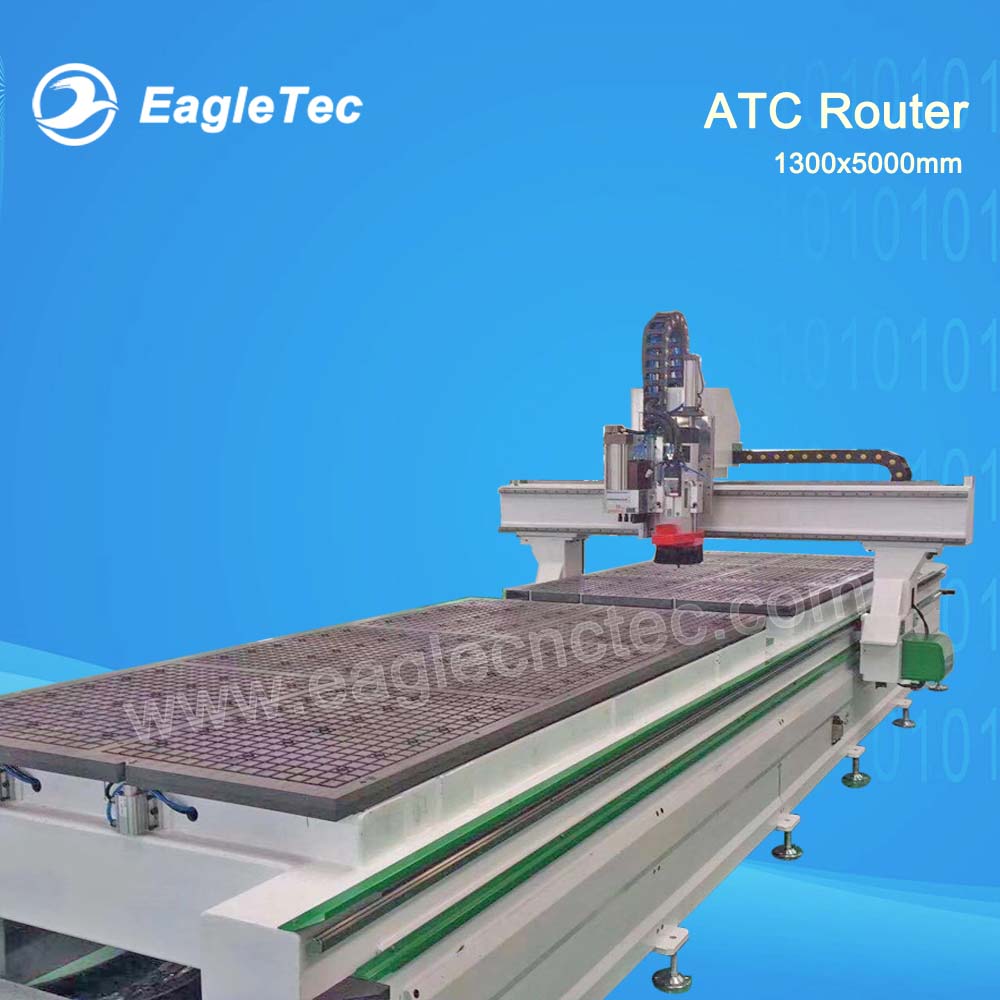

Brief: the unique point of this atc cnc nesting machine is that, it has two working tables and total working size reach to 1300x5000mm. The machine works alternately between the two worktables to improve production efficiency. Assuming the same configuration, a two-station machine can work about 15 to 20 sheets more than a single-station for 8 hours a day. Average output of this machine is 100 sheets 8 hours/day.

Application

This cnc machine is ideal for panel furniture, plate furniture, modern furniture and customized cabinet (include door and body) production.

How a double-table cnc nesting machine improve the efficiency?

Its principle is that, during the machine is processing in the front worktable, we can unload the finished sheet and load a new blank sheet on the rear worktable; same, during machining at the rear table and we can do unload and load on front table. It makes the nesting machine continue to work without stop, so it saves the standby time and improves the production efficiency.

The ATC CNC nesting machine EA-1350DT is the most efficient panel furniture manufacturing equipment even compared with auto loading unloading cnc machine. Why?

In the last paragraph, we have explained how double worktables improve the efficiency. This is just point one.

Point two, this machine is equipped with a carousel type ATC magazine with a capacity of 12 router tools. There is no need to stop machine for tool change, and it only takes 2 to 3 seconds to finish the tool change by carousel tool changer. Therefore, it improves efficiency by saving tool changing time.

Point three, there are a lot of boring (drilling) jobs in the production of panel furniture. The machine is equipped with 5+4 drill unit package, which greatly saves the time spent on the drilling jobs and improves the production efficiency.

Point four, another feature of panel furniture production is that it needs frequent loading and unloading materials. For the solution of this purpose, the machine is equipped with pneumatic material alignment Pop-ups option, which locating the wood sheet quickly, accurately, and automatically.

Therefore, based on the four points above, it is a well-deserved panel furniture production equipment with the highest output.

Quick Details

1300x2500mm x2 working size (double work-stations)

CNC Router ATC spindle 9.0kw (Chinese brand)

Carousel tool changer with 12 tools storage

5+4 drilling unit package

Yaskawa AC servo 1300w

Planetary gear case

SYNTEC CNC controller

Original PMI square linear guides and bearing 30mm

Original Germany Herion rack and pinion

Pneumatic Pop-ups

Detailed Technical Parameter of ATC CNC Nesting Machine 1300x5000mm

Model No. | EA-1350DT

Machine construction | ATC + drill head + double stations

Working size | double worktables 1300x2500mm x2

Machine base | heady duty via VSR treatment, seamless welded from steel tube

Electrospindle | ATC type 9.0KW

ATC magazine | carousel type, 12 tools

Tool change speed | 2 or 3 seconds

Drill package | 5+4 vertical

Motion system | Japan YASKAWA servo motor and servopack 1300w on XYZ

CNC controller | SYNTEC from Taiwan

Linear guide | original PMI from Taiwan 30mm

XY transmission | Germany Herion rack and pinion

Z transmission | TBI ballscrew 30mm

Gear case | Japan Shimpo planetary gear

Sheet wood positioning | pneumatic Pop-ups

Small electronics | Schneider and Omron

Cables | top quality high soft shielding cables with durable performance

Net weight | 4000KGS

Machine dimension | 5550x2200x2000mm

Working voltage | AC380V/50Hz, 3Ph 4 Wire (or other customized option)

Flying speed | 70m/min

Max. machining speed | 40m/min

To get the latest catalog and price of this atc cnc nesting machine, please inquire now.

To check entire panel furniture cnc machine models we have, please click here.

【 Go Back 】 | 【 Close this window 】