Products

|

Product Name:

Nesting CNC Router with Nesting Software for Plate Fitment Production

No. :

EA-1325TL2

|

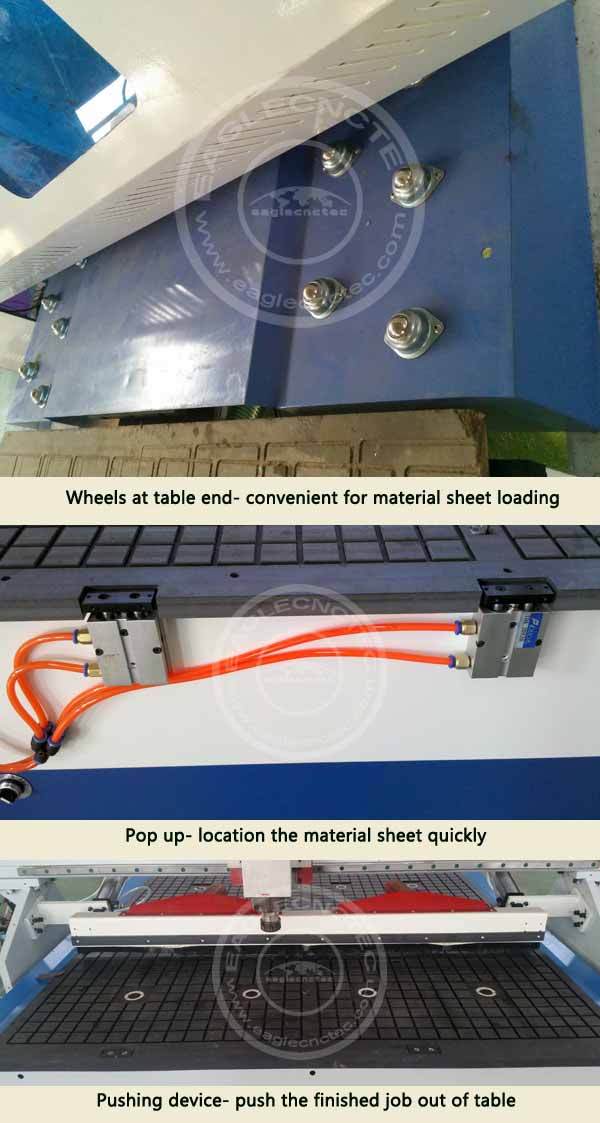

Nesting CNC Router EagleTec-1325TL2 is a pneumatic tool changer cnc router with some special designs which is convenient for plate fitment production. The wheels at table end make the materials loading much easier; the pushing device is used to push the finished job piece out of working table; the pop up device make the material location faster. Compared with common 3D wood cutting CNC machine, cnc nesting router EA-1325TL2 optimized the process of material loading, location and unloading. It saves time cost and improves producing efficiency greatly. Besides this advantage, nesting software improves the utilization of raw materials to the max extent to reduce cost of production. More and more plate fitment manufacturers began to use nesting based cnc wood router to replace the traditional equipment like precision saw and panel saw.

Materials good for nesting cnc router with pneumatic atc

Solid wood, MDF, plastic, PVC, acrylic, and other nonmetal materials

Application

Plate fitment production includes Cabinet, Wood door, Wardrobe, office furniture and etc.

Features of pneumatic tool changer cnc nesting router

1) It’s a high performance-to-price ratio auto tool changer cnc router machine, 2 spindles can be mounted with 2 different kinds of engraving and milling tools, and the tools are changed automatically via spindle shift.

2) Tool magazine can be range from 2PCS to 4PCS.

3) T-slot Vacuum table with 6 vacuum zones, which can adsorb different size materials.

You can also fix the work piece by clamp.

4) Beam is made of steel. A steel beam is superior to a aluminum in it’s ability to

suppress and absorb the forces created during cutting. It is internally ribbed in order to stiffen the assembly; this design is minimizing the vibration while increasing accuracy and repeatability.

5) Has the function of re-carving after break point and power failure.

6) Software: Type 3/Artcam/UcanCAM etc.

7) All the linear guides are centrally lubricated from a central system.

Technical Parameter

Working Size (X Y Z) 1300×2500×200 mm

Driving Motor Servo

Controller NC Studio

Repositioning ±0.02mm

Resolution ±0.0025mm

Command G-code

Max.Traveling Speed 45,000 mm/min

Max.Working Speed 20,000 mm/min

Body Construction Heavy duty type

Work-Holding By vac-sorb

Vacuum Pump 5.5KW, water-ring, 230CBM/hour flow rate

X Y Transmission Helical rack and pinion, HIWIN square linear guide way

Z Transmission Taiwan TBI rolling ballscrew, HIWIN square linear guide way

Spindle 6.0kw, air cooling, 0-18000 rpm variable speed

Collet Size ER32, available diameter of cutter φ3.175-φ20mm

Tool Magazine Pneumatic tool changer, 2 tools

Working Power AC 380V/50-60Hz, 3 Ph 4 Wire

Max.Power Consumption 20KW

Small Electronics Schneider, Omron, CHINT

Net Weight 2000 KGS

The best panel furniture cnc solution will be provided to you after received your inquiry. Please inquire now.